In many areas of life, it is necessary to increase the humidity of enclosed spaces.In industry, many technological processes require controlled humidity levels, e.g. when using paints, adhesives, etc., the manufacturer specifies minimum and maximum humidity levels that must be strictly adhered to, otherwise the quality of the products manufactured will not be satisfactory. We specialise in solving air conditioning and humidification problems that cannot be solved with conventional air conditioning and humidification equipment, or can only be solved in a complex and costly way.

Controlled humidity

Economical operation

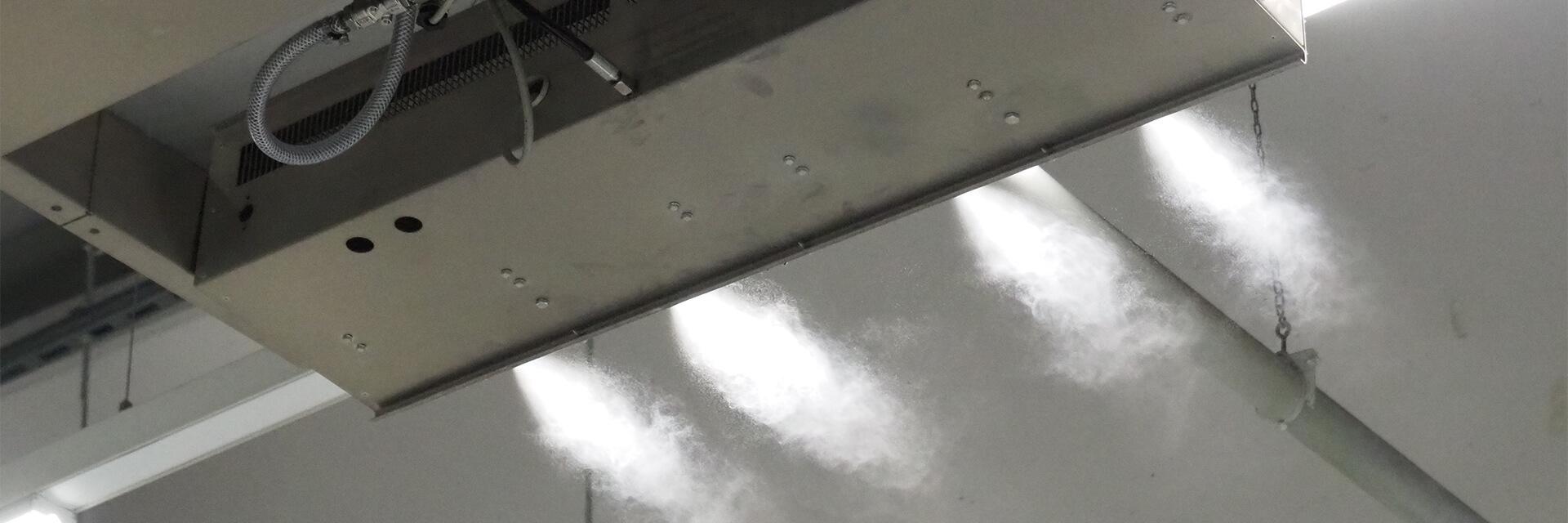

Drip-free operation

Industrial humidification application area PDF download (Hungarian)

Technology humidification

In winter, the air is typically much drier than in summer. Cold air cannot hold large amounts of water because it precipitates quickly. Once the cold, dry air (but of high relative humidity) that is drawn in is heated indoors, the relative humidity is greatly reduced. It can drop to as low as 2-10%. This is extremely low, which can cause all sorts of technological problems and hassles.

Electrostatic discharge

In the electronics industry, low relative humidity increases the risk of electrostatic discharges, which can damage circuits and even production equipment (ESD protection).

Dust, odor damage material binding

Many manufacturing processes generate unwanted amounts of dust and harmful substances. Humidification effectively traps and suppresses dust and odours, even in areas where ventilation is simply not possible or difficult to afford.

Human comfot, humidification at workplace

Fatigue, lack of concentration, dry mucous membranes, weakened immune systems – dry indoor air makes people sick. The humidification system also binds fine dust in the air. Controlled humidity is important not only in production areas, but also in offices, showrooms and conference rooms. In large single-room offices, localised humidification, usually based on ultrasonic principles, no longer provides adequate protection.

Ask our colleague!