Problem

In industry, many technological processes require specific humidity levels. When using paints and adhesives, the manufacturer specifies minimum and maximum humidity levels that must be strictly adhered to, otherwise the quality of the manufactured products will not be satisfactory.

In winter, the air is typically much drier than in summer. Cold air cannot hold large amounts of water because it condenses quickly in the form of precipitation. Once the cold, dry (but high relative humidity) air that is drawn in is heated indoors, the relative humidity is greatly reduced. It can drop to as low as 2-10%. This is extremely low, which can cause all sorts of technological problems and hassles.

In the printing industry, the moisture content of the paper in dry air is reduced, the sheets become electrostatically charged, “sticky” and tear more easily, the ink area and drying time will be inadequate.

In the electronics industry, low relative humidity increases the risk of electrostatic discharges which can damage circuits (ESD protection).

Controlled humidity

Continuous air exchange

Drip-free operation

Solution

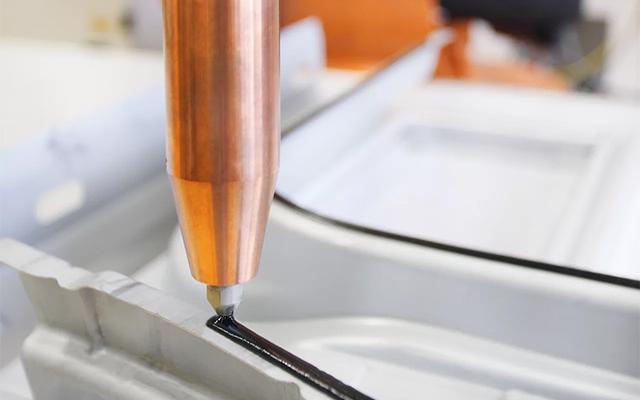

Ditusz Ltd. With the Di-MistAir® HC brand of direct spray humidification systems, makes possible to control the relative humidity of enclosed spaces professionally and easily in an energy-efficient way to ensure that the environment meets the various requirements.

In addition, if the operation of processes or production generates dust (woodworking, metalworking, etc.), the dust can be settled by humidification, reducing the amount of suspended dust.

The operation of the humidification systems is supported via the control equipment developed by Ditusz, combined with our remote monitoring and control software solutions.

Benefits :

+ Controlled humidity

+ Technological compliance

+ Cleaner air

+ Dust, odor, chemical binding

Ask our colleague!

Related Content:

Watch our video to see all the possible uses of humidification/cooling.